Contact Us

0086-411-66665948

0086-411-66665948 sales@dlrtr.com

sales@dlrtr.com joycewang323

joycewang323Products

The standard slew drives are fitted with an open housing and single self locking hourglass worm shaft. Once the power source input is returned to neutral, the worm shaft will lock the load into position without requiring any external braking device.

The slew drive can be with worm gear and helical gear. And also for the inside slewing ring, it can be single-row ball slewing ring, and also can be double-row ball slewing ring. The one with double-row can take much more load. It can be chosen depended on your application.

Below you can find the reference number of slew drive. For the one we do not list as below, please contact with us.

SE Enclosed Slew Drives help power movement across industries and are perfect for situations requiring both load-holding and rotational torque from the same gearbox.

Typical applications include solar trackers, wind turbines, satellite and radar dishes, truck cranes, man lifts, utility equipment, hydraulic equipment attachments, oil tool equipment, tire handlers, digger derricks, and automotive lifts.

SE3C (3 inch slew drive): The number shows the size in inch.

Raceway center diameter: 3inch (76.2mm)

Output torque: 700N.m,

Tilting Moment:1100N.m.

< Click the number to see the detailed drawing for SE and PE type slewing drive

|

Model Data |

Output Torque |

Tilting Moment |

Holding Torque |

Gear Ratio |

Tracking Precision |

Weight |

|

400N.m |

1100N.m |

2000N.m |

62:01:00 |

<=0.2° |

12kg |

|

|

600N.m |

3000N.m |

5500N.m |

62:01:00 |

<=0.2° |

20kg |

|

|

1500N.m |

13500N.m |

10400N.m |

73:01:00 |

<=0.2° |

21kg |

|

|

6.5kN.m |

33.9kN.m |

38.7kN.m |

61:01:00 |

<=0.17° |

49kg |

|

|

7.5kN.m |

54.3kN.m |

43kN.m |

78:01:00 |

<=0.17° |

61kg |

|

|

8kN.m |

67.8kN.m |

48kN.m |

85:01:00 |

<=0.17° |

64kg |

|

|

10kN.m |

135.6kN.m |

72.3kN.m |

102:01:00 |

<=0.15° |

105kg |

|

|

15N.m |

203kN.m |

105.8kN.m |

125:01:00 |

<=0.15° |

149kg |

|

|

18kN.m |

271kN.m |

158.3kN.m |

150:01:00 |

<=0.15° |

204kg |

The SDE series designing is absorbs the advantages of VE and SE. The Azimuth and Elevation 3D direction rotating at the same time.

The most common slewing drive application for the dual-axis slewing drives are dual-axis solar trackers, such as heliostats and concentrated photovoltaics (CPV), and satellite or radar dishes. Other applications include automotive lifts, robotic arm positioners, and stage equipment.

< Click the number to see the detailed drawing for SDE type slewing drive

|

Model Data |

Output Torque |

Tilting Moment |

Holding Torque |

Gear Ratio |

Tracking Precision |

Weight |

|

400N.m |

500N.m |

2000N.m |

62:1 |

<=0.2° |

32kg |

WE series slewing drive is similar to the SE, but the difference is designed with curved tooth slewing ring, the output torque is increased, with the smooth running of a superior anti-sandstorm, field use, etc.

The WE series is a good choice when you are in the Wild harsh working conditions and need anti-glued more stronger.

< Click the number to see the detailed drawing for WE type slewing drive

|

Model Data |

Output Torque |

Tilting Moment |

Holding Torque |

Gear Ratio |

Tracking Precision |

Weight |

|

8kN.m |

33.9kN.m |

38.7kN.m |

62:01:00 |

<=0.15° |

48.5kg |

|

|

10.8kN.m |

67.8kN.m |

48kN.m |

86:01:00 |

<=0.13° |

68kg |

|

|

12.96kN.m |

135.6kN.m |

72.3kN.m |

104:01:00 |

<=0.1° |

90kg |

|

|

28.7kN.m |

203kN.m |

105.8kN.m |

90:01:00 |

<=0.1° |

169kg |

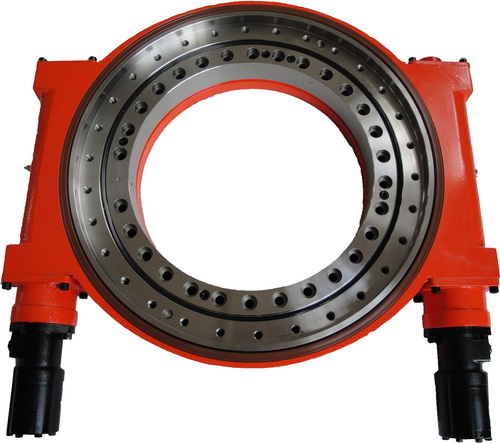

The HSE type slewing drive is mainly designed for the hydraulic module car. Since the slewing bearing is the main part, this system has stronger dynamic axial load and tilting moment.

< Click the number to see the detailed drawing for HSE type slewing drive

|

Model Data |

Output Torque |

Tilting Moment |

Dynamic Axial Rating |

Gear Ratio |

Tracking Precision |

Weight |

|

21.8kN.m |

169kN.m |

265kN |

82:01:00 |

<=0.15° |

186kg |

|

|

25kN.m |

271kN.m |

590kN |

94:01:00 |

<=0.15° |

255kg |

|

|

43.6kN.m |

52.3kN.m |

265kN |

82:01:00 |

<=0.15° |

206kg |

|

|

50kN.m |

271kN.m |

590kN |

94:01:00 |

<=0.15° |

275kg |

The S open hourglass is excellent for low-cost manufacturing equipment that requires daily maintenance and checks or doesn’t need to be covered.

Typical uses for this S open-housing slewing drive include many mobile applications such as man-lifts, utility equipment, turntable applications, digger derricks, and steering applications.

|

Model Data |

Output Torque |

Tilting Moment |

Holding Torque |

Gear Ratio |

Tracking Precision |

Weight |

|

6.5kN.m |

33.9kN.m |

38.7kN.m |

61:01:00 |

<=0.2° |

42kg |

|

|

7.5kN.m |

54.3kN.m |

43kN.m |

78:01:00 |

<=0.2° |

48kg |

|

|

8kN.m |

67.8kN.m |

48kN.m |

85:01:00 |

<=0.2° |

55kg |

|

|

10kN.m |

135.6kN.m |

72.3kN.m |

102:01:00 |

<=0.15° |

87kg |

SE-2 Series slewing drives are combined by VE Housing, slewing ring, two hourglass worm and some Matching parts, it achieved 2 times of tooth contacting. In the same volume and installation space, it improved nearly double output torque, greatly improving the product's performance.

< Click the number to see the detailed drawing for Dual worm type slewing drive

<

|

Model Data |

Output Torque |

Tilting Moment |

Holding Torque |

Gear Ratio |

Tracking Precision |

Weight |

|

6.5kN.m |

33.9kN.m |

38.7kN.m |

61:01:00 |

<=0.2° |

42kg |

|

|

7.5kN.m |

54.3kN.m |

43kN.m |

78:01:00 |

<=0.2° |

48kg |

|

|

8kN.m |

67.8kN.m |

48kN.m |

85:01:00 |

<=0.2° |

55kg |

|

|

10kN.m |

135.6kN.m |

72.3kN.m |

102:01:00 |

<=0.15° |

87kg |

Normally we have hydraulic motors and electric motors for the slew drives, we can choose the suitable model according to your specific requirement.

深沟一侧的内、 外比赛球路径减少肩薄轴承。Snapover 大会允许使用的一种---一块圆形口袋环分离器和更大的球补充。A 型轴承需要推力的应用建立接触角。股票轴承是个别单位和当作为购买这样必须在安装到所需的运行预紧力或间隙调整。...

Hot tags : thin section bearing thin bearing thin wall bearing

康拉德组装截面薄壁轴承为涉及多个负载的应用而设计。独特的内部几何形状允许应用程序的径向负荷、 推力负荷在两个方向和力矩载荷的单独或任何组合。单个四点接触薄轴承可能取代两个轴承在许多应用程序中。...

组装好的薄轴承主要用于径向负荷深球槽的应用程序还允许推力负载中的应用两个方向 — — 常与另一个轴承相结合的康拉德。

康拉德组装截面薄壁轴承为涉及多个负载的应用而设计。独特的内部几何形状允许应用程序的径向负荷、 推力负荷在两个方向和力矩载荷的单独或任何组合。单个四点接触薄轴承可能取代两个轴承在许多应用程序中。...

SC ... V UU 部件号 主要尺寸和安装尺寸 (mm) 基本额定载荷 Weight(g) h D L W H G A E B C S1 × e S2 dyn.c stat.co SC8V UU 11 17 15.4 34 22 18 6 5 24 7.7 M4 × 8 3.4 274 392 27 SC10V UU 13 20 19.9 40 26 21 8 6 28 9.95 M5 × 1...

Hot tags : linear module